In the early 1920s, as Chattanooga began to develop into the 20th century, local businessmen set out to solve a pressing problem: they needed a local source of cement.

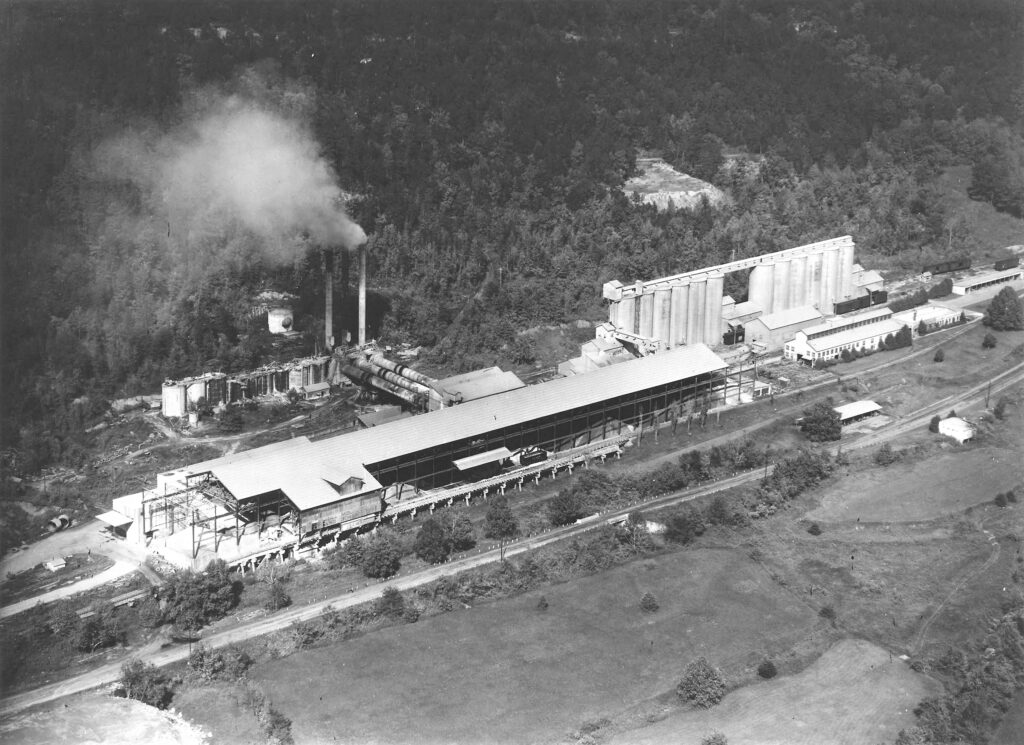

Their new idea soon became a new factory. On the Suck Creek side of the Tennessee River, under the foot of a then-quiet Signal Mountain, the Signal Mountain Cement Co. began production on Oct. 12, 1923.

Today, 100 years later, the facility is still producing.

Owned by the Buzzi family of Italy, the Signal Mountain plant – known as Buzzi Unicem USA – produces a staggering 930,000 tons of cement annually.

“There’s a good chance if you buy concrete in Chattanooga, there’s a very good chance you’re using our cement,” said David Puzan, plant manager.

Buzzi Unicem USA’s Signal Mountain facility recently celebrated its 100th year, with formal and informal events that united current and former employees in multiple historic gatherings. The plant is a spectacle of engineering; if you only think it makes concrete, then, think again.

“Cement is the most widely consumed commodity after water, ” said Puzan.

Buzzi Unicem USA’s Signal Mountain plant’s longevity is a rarity among American cement-producing companies; when Puzan began in the industry over 40 years ago, there were approximately 170 cement plants and 400 active kilns in the US. And now?

“Today there are fewer than 100 operating facilities in the US,” he said.

Cement is the main ingredient in concrete, which is used in construction and infrastructure development. Concrete is a mixture of aggregate and paste, the latter of which is Portland Cement and water, which binds with the aggregate to form concrete.

Twenty-four hours a day, 365 days a year, Buzzi employees – averaging around 120 at both the Signal plant and a nearby quarry combined – are operating the plant.

It all begins with limestone.

The original plant ran into trouble in the 1950s, as its initial quarry was operating under a growing Signal Mountain.

“You can’t dynamite under Signal Mountain when people are building homes,” Puzan said.

“So, the company entered into a lease agreement with the Tennessee River Gorge Trust to mine limestone at our current quarry near Bennett’s Lake in Marion County”, Puzan said.

Today, limestone and other raw materials are shipped via barge to the Signal Mountain site where a series of conveyors transport the materials to designated silos and bins. A vertical mill pneumatically pulverizes the materials which are then conveyed to a rotary kiln and then onward through a finishing mill.

“The kiln is the heart of the cement plant. Temperatures in the burning zone can approximate 2800 degrees Fahrenheit,” Puzan said.

To witness Buzzi’s Signal Mountain facility up close – the Pyro process eight-story tower, enormous crushing mills, a control room with 22 screens and a massively hot kiln – is to experience a stunning tour of engineering brilliance.

Buzzi’s cement is shipped on railcars and bulk tankers to its main buyers – yes, Ace Hardware is a client – in Chattanooga, Atlanta, Knoxville and Nashville.

Puzan, who hails from western NY and has been in the cement industry for more than 40 years, said these last few years have been full of change industry wide. For example: the cement industry – historically one of the world’s heaviest carbon polluters – is committed to carbon neutrality by 2050, Puzan said, adding that his plant is aiming for 2030.

Cement originated with the Romans – “brilliant,” Puzan calls them – who perfected the art of cement-making; the process became lost until the 1800s, when an English bricklayer patented the cement-making process, naming it for a nearby isle of Portland.

Puzan stops to point out a wall of safety awards.

“We’re looking out for each other,” he said, before later adding: “The Buzzi family cares about people.”

One century after the original vision of those 1920s business leaders, Signal Mountain’s Buzzi Unicem USA facility continues to improve the lives of countless people.

“If you own a home, you may have poured concrete sidewalks and driveway. If there’s brick on your home, then mortar is holding the bricks in place. When you drive on local roadways with curbs, sidewalks and bridges, concrete is an integral part of the structure,” Puzan said. “Cement provides infrastructure to where we’re going and where we live.”