Recent science has made clear that man-made pollution is the predominant contributor to Earth’s warming climate, leading to consequential threats to societies, economies, biodiversity and vulnerable populations in communities worldwide. As a result, businesses and consumers are starting to assess and act on proactively minimizing how their operations contribute to climate change.

Why should businesses embed sustainability into their values and core operational policies and practices? A major reason is because top talent and customers are increasingly partial to supporting companies that are ambitious in taking ownership of their responsibilities for fostering a healthy and livable global climate.

Chattanooga continues to draw record visitation and national notoriety for its scenic beauty and other natural assets, as well its emerging green economy — in particular, high-skill and living-wage jobs associated with the approaching demand for mass electrification of the nation’s vehicle fleet.

Electric vehicles, however, are only one piece of a diverse and complex need to reduce emissions across multiple sectors nationwide, and in our community: A 2018 City of Chattanooga inventory revealed more than 2.9 million metric tons of heat-trapping emissions were emitted inside city limits. Landfill diversion, buildings and energy present huge opportunities to transition toward a cleaner cost of doing business, in addition to tailpipe emissions from the transportation sector. These opportunities create and fill the green jobs needed to ensure those transitions materialize.

“Chattanooga Chamber members consistently tell us our region’s natural resources and scenic beauty are a primary benefit to doing business and living here,” says Justin Groenert, Vice President, Public Policy, Chattanooga Area Chamber of Commerce. “While businesses have a moral imperative to reduce their carbon footprint, most of the time it also makes good economic sense to do so. The good thing to do for the environment is often one and the same as what’s needed to reduce the cost of doing business. That’s why the public policy agenda we’ve put together with our members includes a focus on energy efficiency and conservation.”

Many of America’s Fortune 500 companies are setting emissions-reduction targets that are consistent with those in the Paris Climate Agreement, what climate scientists have recommended is needed to avoid “catastrophic” global warming (no more than 2 degrees Celsius this century). Many more publicly traded companies are likely to follow suit, as the Securities and Exchange Commission issued a draft rule in March that could require registrants to report on their climate-related risks and financial metrics, as well as their greenhouse-gas emissions.

While “carbon footprint” has become part of the modern vernacular on a climate-altered planet, what does that term mean in a private-sector context, from small businesses to large corporations? It’s basically the most comprehensive estimate of total greenhouse-gas emissions produced to directly and indirectly operate a business.

The Greenhouse Gas Protocol, a partnership between the World Resources Institute and the Business Council for Sustainable Development, categorizes greenhouse gas emissions into three Scopes. Scope 1 and 2 emissions are typically straightforward to identify and account for, such as all the fuel burned on a business or industrial site and the purchased power from local utilities. Scope 3 emissions fall largely outside of a company’s direct oversight and can be more difficult to both calculate and cut into or offset (such as what happens to a company’s products at the end of their lifecycle).

The Appalachian Carbon Exchange is a nonprofit startup affiliated with the Tennessee River Gorge Trust. Through forestry-based projects in Tennessee and Appalachia, ACE provides companies with a market-based offset solution to meet their net-zero-carbon targets – meaning, those seeking an innovative solution to mitigate their Scope 1 and Scope 3 emissions that comes with a tangible, positive impact close to home. “ACE was founded to incentivize landscape-scale conservation and reforestation by increasing ESG investments that stay within the Appalachian region,” says ACE Director Ongeleigh Underwood. “We provide a farm-to-table solution for carbon offsets, where traceable emission creation and verified carbon sequestration occur within a day’s drive. This increases transparency and trust in the process while strengthening our community’s connection.”

TREND set out to learn whether Chattanooga’s major companies – those likely equipped with existing resources, values and culture — had taken steps consistent with best practices in sustainability: namely, completed a comprehensive inventory of greenhouse-gas emissions generated by their operations, as well as established a target, strategy and tactics to reduce those emissions.

Volkswagen Chattanooga — VW sources renewable energy to mitigate the CO2 impact tied to local factory operations. Last year, their 33-acre, 9.5-megawatt solar park generated approximately 12-million kilowatt hours of electricity, or 10% of the factory’s total demand. Through TVA’s Green Flex program, VW Chattanooga then purchases renewable energy credits (RECs) to supply the remainder of their clean electricity needs. Compared with a 2012 baseline, VW has achieved a 70% reduction in CO2 generated per-vehicle during their manufacturing process.

Unum – The disability, accident and life insurance company has completed a near comprehensive inventory of their Scope 1, Scope 2 and Scope 3 greenhouse-gas emissions including the impact associated with their employees’ commute and business travel, and is annually reporting this information to the Carbon Disclosure Project (CDP). Unum has set a 3% year-over-year reduction target for these emissions, and so far has been well exceeding their target including a 20% decline in greenhouse-gases for 2021 and a 15% decline in 2020 – largely due to leasing and employee-occupancy changes for Unum’s office buildings during COVID-19. Other investments to reduce Unum’s carbon impact include: LED lighting conversions, energy-efficient equipment including in their kitchens, improved HVAC systems, EV-charger installations, and for their United Kingdom operations, the purchase of renewable energy credits. Chattanooga, Portland, Maine and Columbia, South Carolina employees can also compost their food waste at Unum facilities. Locally, hauling services are provided by Chattanooga-based New Terra Compost.

The company is currently working to convert their facilities’ waste and water usage into a carbon metric in order to account for that impact in their emissions inventory.

In 2020, Unum also made a strategic internal decision to securely recycle paper documents that did not require a physical copy to be kept on file, recycling 674,036 pounds of paper – saving the equivalent of 1,685 cubic yards of landfill space and 5,655 trees. Paperless options also enabled Unum to meet the demands of a remote workforce during the pandemic. All paper is sourced from sustainably managed forests, and the company continues to stand up programs to reduce paper usage and help their consumers adopt digital versions of their healthcare records.

Unum believes implementing business strategies that focus on environmental dimensions of their operational footprint creates long-term value for stakeholders and integrates ESG factors into investment decisions.

BlueCross BlueShield of Tennessee — BCBST believes prioritizing sustainability is an investment in both the future of their business and in communities statewide. “We know that social determinants of health include access to clean air, clean water and a stable climate – and sustainability efforts that support cleaner air and water ultimately benefit Tennesseans with issues like asthma and cardiovascular disease,” says Thomas Nutt, Manager of Properties Engineering & Maintenance, BCBST.

Similar to Unum, the arrival of COVID-19 served as an opportunity for positive environmental impact through operational changes needed to respond to pandemic conditions. For example, avoided employee-commute travel, which in 2021 represented 20% of BCBST’s carbon impact, resulted in an 84% decline in their CO2 emissions between late 2018 and late 2021. The waste stream generated at their Cameron Hill and Gateway facilities also dropped by more than 50% in 2020, and by another 33% in 2021.

BCBST’s Chattanooga campus is certified LEED Gold, and the Memphis office LEED Platinum. A state-of-the-art solar installation on the Chattanooga campus benefits BCBST’s business and the city as a whole: 497,000 sq. ft. of unused rooftop and blacktop space is instead used to support solar panels. As a result, 37% of the energy needed to power BCBST’s Gateway and Cameron Hill facilities is being met with solar, saving the company nearly $530,000 in annual energy costs and returning more than 312,000 kWh to the local grid.

“As we move forward, we invite our employees, business partners, communities and civic leaders to join us in multiplying the impact of these sustainable choices and investments,” says Nutt.

Buzzi Unicem USA — Cement is the basic ingredient of concrete, the most widely used construction material in the world; its production comes with a significant climate impact, accounting for around 8% of total CO2 emissions globally. Meanwhile, the floor area of the world’s buildings will double in the next 40 years; meaning, cement production will increase by 25% from today (over four times 1990 levels). Therefore, efficiency gains alone won’t be enough to meaningfully cut into the industry’s emissions.

On the heels of the 2015 Paris Climate Agreement, Buzzi Unicem USA developed carbon commitments that extend to all countries in which they operate. The company actively partnered with Portland Cement Association in developing PCA’s Roadmap to Carbon Neutrality, which focuses on the product’s entire value chain, from the cement plant all the way through the lifecycle of its use in the built environment. In producing cement, Buzzi’s Chattanooga plant has replaced use of traditional fossil fuels with a tire-derived fuel instead, resulting in a 30% lower carbon intensity.

By year-end Buzzi will have fully converted their cement product to one with a much lower carbon impact, Portland limestone cement. Buzzi’s Chattanooga manufacturing plant has also earned U.S. EPA’s ENERGY STAR® certification for 13 consecutive years, which recognizes superior energy performance for industrial facilities (only the top 25% percent of the plant’s domestic peers achieve this certification).

Kordsa – Kordsa Inc. — a subsidiary of Kordsa Global, a global player in tire, construction reinforcement and composites markets — reinforces one out of every three automobile tires and two out of every three aircraft tires worldwide. Chattanooga-based Kordsa Inc. handles a lot of that manufacturing work domestically.

In November 2021, Kordsa hired Chattanooga’s first in-house environmental professional and is currently in the process of hiring an onsite sustainability professional. For 2022, they aim to reduce CO2 emissions by 4.2%, water usage by 2.2% and landfilled waste by 6.2%. All Kordsa sites located around the world are aiming for Net Zero carbon by 2050; as such, the Chattanooga facility expects to set its emissions-reduction targets to align with this Net Zero goal in the very near future. Earlier this year, Kordsa also established an internal committee for the sole purpose of generating and following through on sustainability-related projects.

Kordsa is working to implement two small pilot projects aimed at reducing onsite wastewater generation; the results of these pilots will inform whether Kordsa can expand those solutions throughout their local facility. Kordsa Chattanooga is also continually looking for landfill-diversion opportunities including overall waste prevention and reduce-reuse-recycle tactics for all materials needed to support their operational needs.

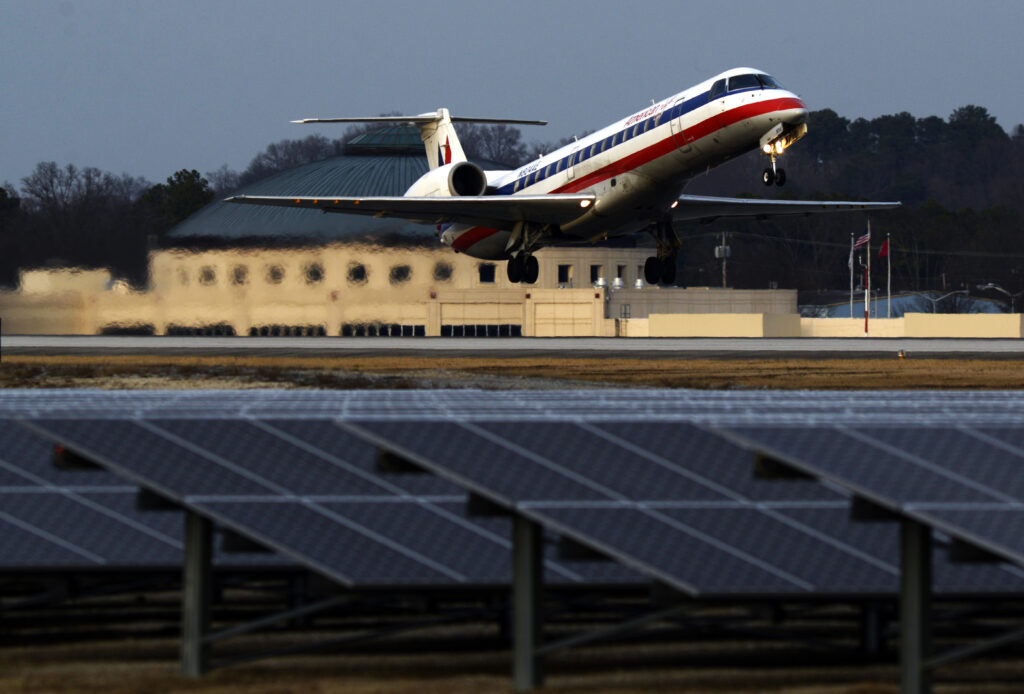

Chattanooga Metropolitan Airport – A little over a decade ago, the Chattanooga Airport got into solar energy, with a three-phase buildout of 21 megawatts of power spanning 7 to 8 years. Today this upfront capital investment in solar on their western airfield, utilizing what would have been otherwise undevelopable land, has put CHA in a position to now sell power back to TVA and offset their EPB electric bills. This, in turn, keeps costs down for the Airport Authority so that fees can remain low for travel activity in and out of the Chattanooga region. Recent efforts build on the 21MW array by partnering with EPB on a pilot battery storage project for solar-generated energy, where the airport site could become its own “mini microgrid.”

Other recent efforts include: a partnership with CARTA and with Tesla to install 10 publicly-available EV chargers (five each), a first-of-its-kind LEED Platinum certification for an airport terminal, a LEED Gold certification for an airport hangar, and a LEED Silver honor for terminal renovations; a repurposing of concrete rubble from an onsite construction project to serve as ground cover for the solar array; and a recycling of 1990s carpet tiles (made into new carpet tiles in another part of the airport).

A climate-adaptive stormwater project on Brainerd Road capitalized on grant funds to remove impervious asphalt surfaces that were causing excessive ponding near one of the airport’s FAA-mandated “runway protection zones,” instead converting the area into a green-grass site with new understory trees. As a result, stormwater that was formerly flooding surrounding neighborhoods during increasingly frequent heavy rain events is now captured by green infrastructure and diverted into a nearby creek.

Lodge Manufacturing – When cookware manufactured at their South Pittsburgh foundry doesn’t meet Lodge’s quality standards, they just melt it back down and begin again. In addition to iron, Lodge reuses the sand needed for their mold-casts until it’s no longer viable, then donates any leftover sand for reuse in construction projects (such as building foundations). Their 2021 waste-reduction and recycling efforts resulted in diverting from landfill: 252 tons of steel shot, 15.9 tons of seasoning oil, 224 tons of cardboard, 16.2 tons of shrink wrap, 10 tons of mixed paper and 1,000 cubic yards of spent foundry sand.

Chambers for Innovation and Clean Energy exists as a resource organization for Chambers aiming to help businesses reduce their emissions and power their operations by clean energy: “As community-based and community-minded organizations, Chambers that do so can create a community dialogue around sustainability but also help businesses establish a collective voice, for example, around needed policy changes within utility service areas for better access to renewable energy products,” says Ryan Evans, Director of Chambers for Innovation and Clean Energy.

As companies make the shift toward considering their stakeholders as well as their shareholders, they can claim a competitive edge and increase profitability by offering long-term value to customers, investors, employees, suppliers, and society writ large. That’s because a company’s stakeholders have a vested interest in mitigating climate change, but also in maintaining clean air, land and water in the communities where they do business.

“Chambers and their member businesses are interested in being part of the sustainability conversation because it makes good business sense,” says Evans. “While improving efficiencies within your buildings and electrifying your vehicle fleet can require greater upfront capital expense, these measures generally lead to significantly decreased operating costs. Chambers are incentivized to try to do as much as they can to help their members as well as their communities to start thinking about cleaner solutions.”